Hot melt damping pad

SnugDam 203 mainly uses EVA (non magnetic) and magnetic powder (magnetic) as the main materials. The product has no binding layer and is directly laid onto the electrophoresis board. After high-temperature baking, it has long-term adhesion and good shock absorption, ensuring the durability and comfort of the vehicle.

Product features

It has a good shock absorption and noise reduction effect on cars.

|

Project |

Specifications | |||

| non magnetic | magnetism | |||

| appearance | Base material | No obvious visible particles in the material | ||

| Initial sample | The surface is smooth and free from defects such as particles, wrinkles, bubbles, layering, and fractures | |||

| After standard baking | Good adhesion with sheet metal, smooth surface, without defects such as particles, wrinkles, bubbles, delamination, and fractures | |||

|

Density(g/cm3) |

≤1.6 |

≤2.0 |

||

| size | Meet the requirements of the design drawings | |||

|

Shear strength(Mpa) |

initial |

≥0.5MPa |

||

| Anti shrinkage |

Over baking(200℃×30min) |

≤2% |

||

|

Standard baking(160℃×30min) |

||||

|

Underbaked(140℃×30min) |

||||

|

nonvolatile matter(%) |

≥99% |

|||

| anti-sagging |

-10℃ |

/ |

No warping, detachment, displacement ≤ 20.mm | |

| Standard conditions | ||||

|

200℃×30min |

||||

| flexibility |

-40℃ |

Rotating around the mandrel without breaking | ||

| Anti adhesion |

40℃*14d |

non-sticky | ||

| corrosion resistance | Neutral salt spray 480h | No visible corrosion on the plate | ||

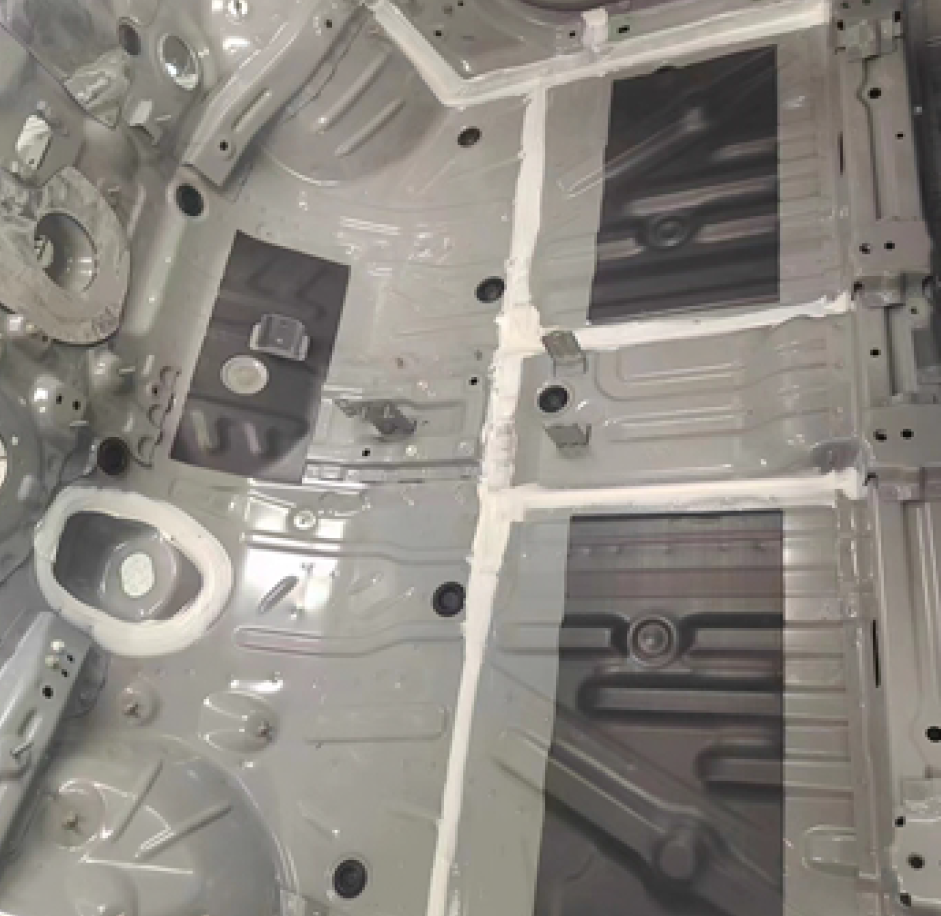

- The painting workshop is directly laid on the car doors, side walls, vehicle floor, and other positions. After high-temperature baking, it has good bonding effect with sheet metal.

The color of the damping film is black or other colors required by the customer.

After cutting into pieces, use cardboard boxes/plastic turnover boxes for packaging or packaging according to customer needs.

This product is non hazardous and has a shelf life of 6 months at room temperature in a cool and dry place.